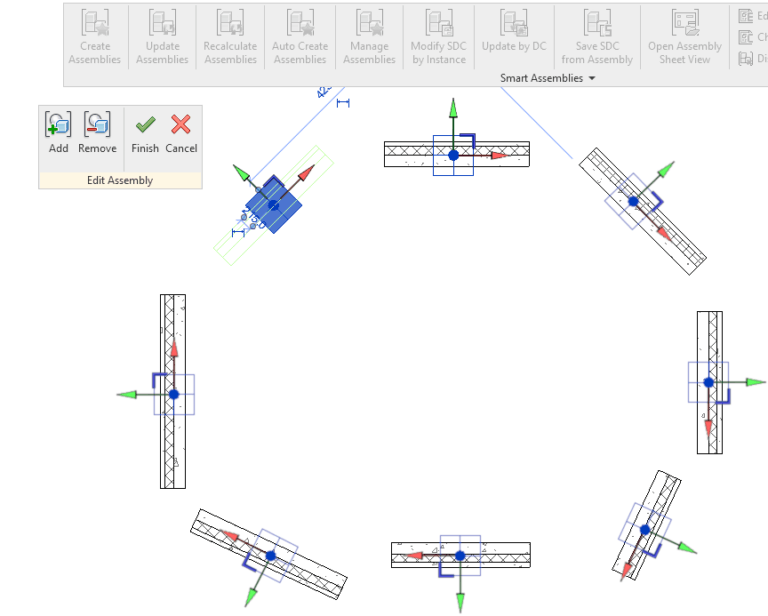

Quickly prepare shop drawings

Smart Assemblies creates assemblies and corresponding views from Walls, Parts, Floors, Structural Framing, Architectural Columns, Structural Columns, or Structural Foundations you select in a Revit® project. The software automatically generates dimensions in views by predefined rules. Assembly sheets are generated automatically by a predefined sheet template where views and schedules are placed in the right places.

Smart Assemblies provides a powerful set of functions for preparing shop drawings:

- An assembly combines multiple hosted or nested concrete and steel elements into a single entity that can be dimensioned, scheduled, tagged, and isolated to create assembly views and sheets.

- Automatically rotate assembly origin for walls, beams, columns etc.

- Control / manage / update changes in assemblies with Dynamic Smart Assemblies Update.

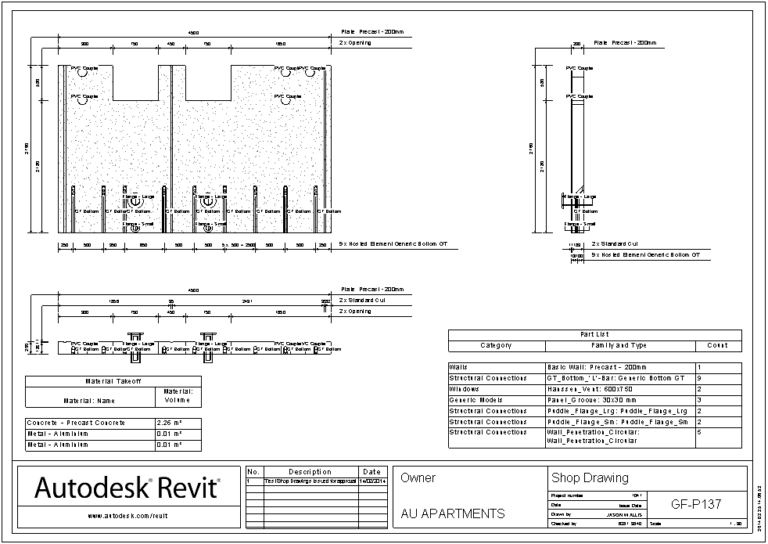

- Assembly views and sheets are automatically generated by the current Shop Drawing Configuration.

Schedules and sheets are grouped and displayed in a separate tabs in Shop Drawing Configurations dialog.

Possibility to create two or more sheets if needed.

- Flipped version of default Revit views can be created at once using Shop Drawing Configurations window of Smart Assemblies.

- Creates assemblies and views by manually defined Configuration Name in the shared parameter – Smart Assembly Configuration.

- Possibility to find/select/isolate Primary and Secondary Assemblies.

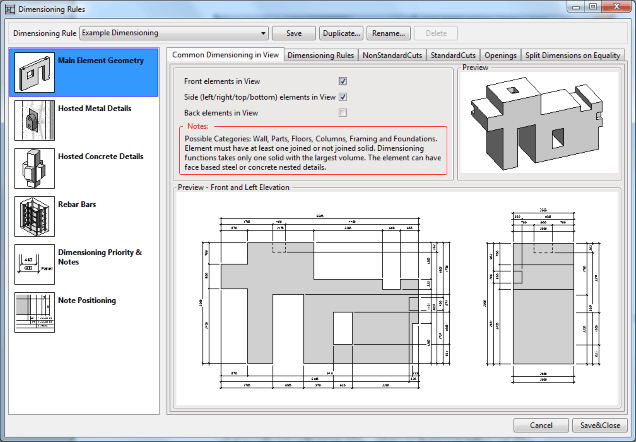

- Defines dimensioning settings for:

Walls, Parts, Floors, Structural Framings, Architectural and Structural Columns or Structural Foundations.

Hosted Concrete Details. Possible categories: Structural Framing and Structural Connection. Details have to be created as Face Based families with Concrete material behavior.

Hosted Metal Details. Possible categories: Structural Framing and Structural Connection. Details have to be created as Face-based families with steel material behavior.

Hosted Rebar.

- Floor Slab Edges are included in the assembly.

- Defines the Views that have to be created for the assembly, the same as:

- Dimensioning Configuration for every view

- Schedules

- View/schedule templates

- Tags

- Legends

- Title block

- Sheet Template – an existing sheet where views, schedules, legends are placed in the required places. New assembly sheets will be generated automatically by a predefined sheet template.

- Adds additional “Assembly Mass” parameter to the assembly and calculates true mass value automatically. Mandatory condition for mass calculation is that every element has to have material assigned with “Density” value.

- Adds additional “Element Mass” parameter to every assembly element and calculates true mass value automatically. Later this parameter can be included in the assembly schedule.

- Possibility to change element orientation in the assembly views.

- Possibility to insert Gravity Point in the assembly. Assembly sheets are generated automatically by a predefined sheet template where views and schedules are placed in the right places.

- Recalculate Assemblies – recalculates Gravity Point position of the assembly and moves it to the updated place — no need to update assembly views.

- Updates selected assemblies by predefined Shop Drawing Configuration.

- Saves section’s position and direction.

- Possibility to show assembly schedule counts by assembly instance or assembly type.

- Saves Shop Drawing Configuration settings in every assembly for the future updates.

- Possibility to select view options – show view symbols, gravity point, grids, tags, tick if views should be updated.

- Saves Shop Drawing Configuration settings in separate XML files. This can be placed into a network server for multiple users to access.

- Shows detailed report with warnings after making or updating the assembly. Report can be exported to PDF file if necessary.